Weckenmann Tilting Tables

Tilting Tables

Tilting tables offer a lot of flexibility and are used in the manufacture of various precast concrete parts.

Customised Weckenmann tilting tables allow the horizontal production of walls, facades and special elements. Our production tables have premium-quality mould faces and high-frequency vibrators for perfect concrete compaction. The individual side rails can be customised. Our users produce premium-quality precast concrete parts with our tilting tables, which can be set upright to about 80 degrees with integrated tilting hydraulics or with a tilting mechanism in conjunction with the overhead crane to facilitate demoulding.

The tilting movement is executed by two or more parallel-operating hydraulic cylinders or a tilting mechanism with support in the vertical position for crane application.

Fixed high-frequency vibrators (optional) below the tilting table guarantee optimum concrete compaction. The compaction energy is infinitely adjustable by a frequency converter. The optional heating system supplies heating pipes attached below the shuttering sheet with hot water or thermal oil.

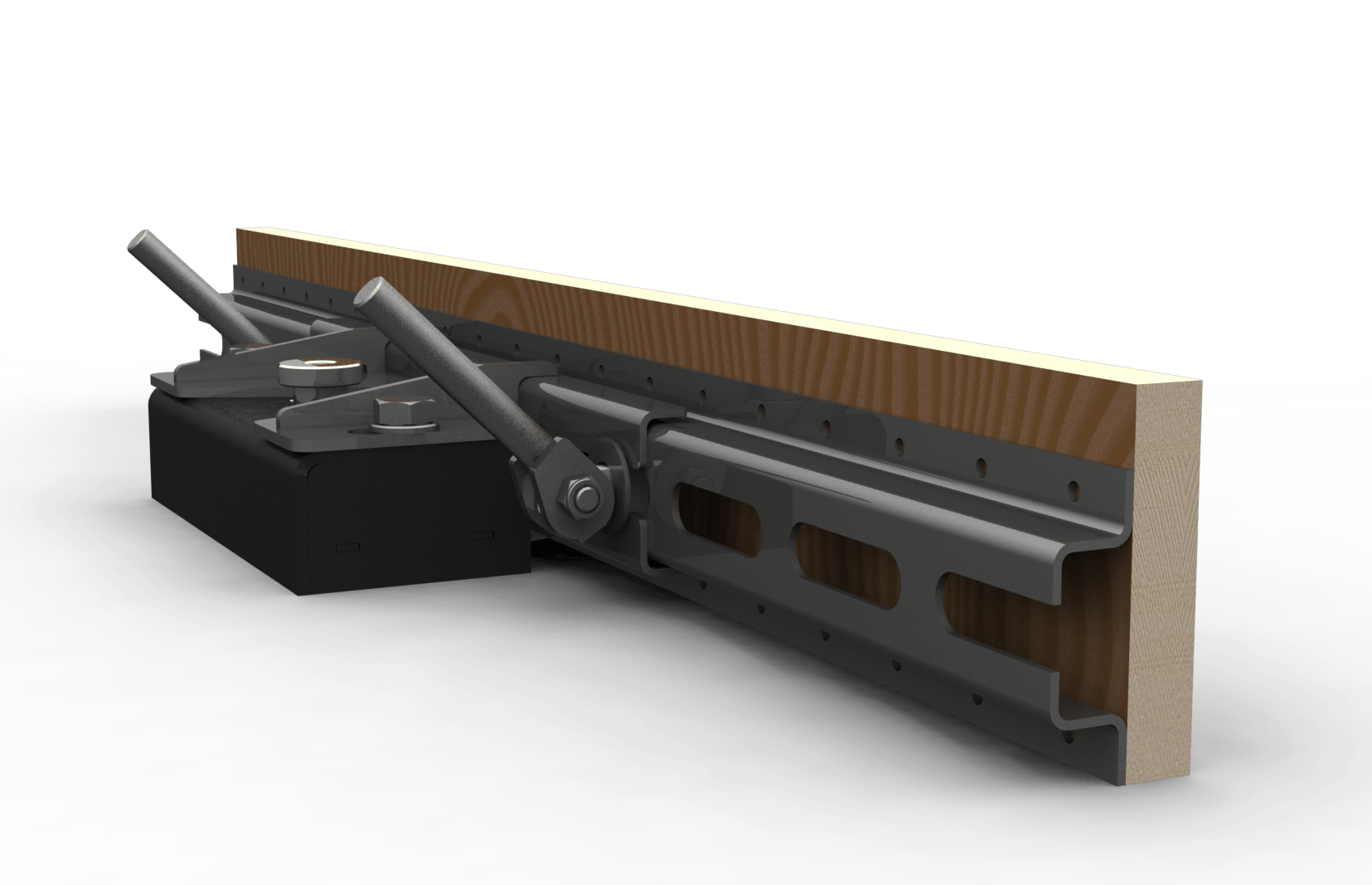

Structure of a tilting table:

- Special shuttering steel with special flatness grade and ground formwork surface.

- The shuttering sheet is welded onto a stable and torsionally rigid substructure. The tilting table is securely bolted to the floor.

- Lifting hydraulics or lifting mechanism.

- Optional heater for hot water or thermal oil for even and energy-saving heating of the precast parts.

- Fixed or infinitely height-adjustable side rail profiles depending on the concrete part.

- Concrete compaction is carried out by fixed/integrated high-frequency vibrators, which are powered over a frequency converter.

- Several tilting tables can be combined with each other and extended with an insert bridge.

Technical Facts

Length

up to 15mtrs

Width

up to 4.5mtrs

Tilt Angle

76°

Load Capacity

up to 1,000 kg/m²

Side Rail Heights

100 - 360mm